Are you tired of noisy generators disrupting your peace and quiet? Do you want to enjoy uninterrupted power supply without having to put up with the noise levels of a standard generator? Building a DIY soundproof generator box can help muffle the noise levels and create a more enjoyable environment for you and your family. In this article, we will walk you through the steps of building your own DIY soundproof generator box.

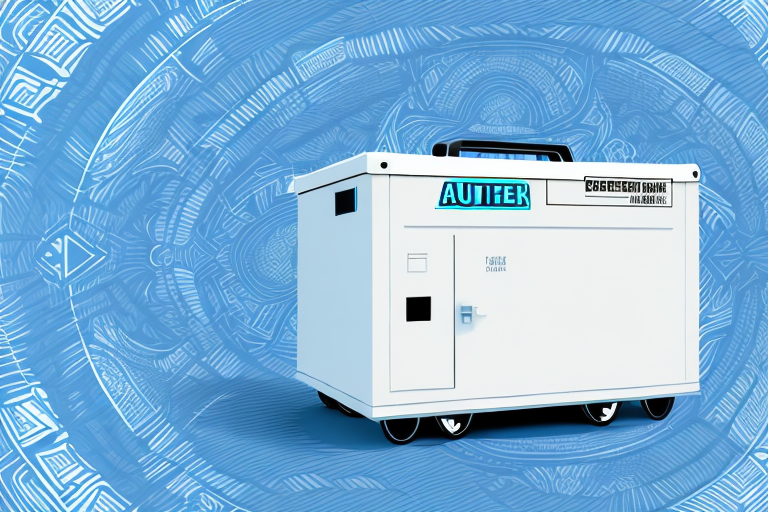

Understanding the Importance of a Soundproof Generator Box

A soundproof generator box is crucial in reducing the noise levels of generators. The noise from generators can be very loud and can potentially cause hearing damage and irritate your neighbors. Additionally, prolonged exposure to high levels of noise can be detrimental to one’s physical and mental health. Building a soundproof generator box not only helps reduce noise levels but also lengthens the lifespan of your generator by protecting it from outdoor weather elements.

Another benefit of a soundproof generator box is that it can improve the overall efficiency of your generator. When a generator is placed in an enclosed space, it can create a vacuum effect that helps to draw in cool air and expel hot air. This can help to regulate the temperature of the generator and prevent it from overheating, which can cause damage to the engine and other components.

It is important to note that not all generator boxes are created equal. When building or purchasing a soundproof generator box, it is important to consider factors such as the size of your generator, the materials used in the construction of the box, and the ventilation system. A poorly designed generator box can actually increase noise levels and cause damage to your generator, so it is important to do your research and invest in a high-quality product.

Materials and Tools Required for Building a Soundproof Generator Box

The materials you need to build a soundproof generator box include plywood sheets, screws, hinges, latches, acoustic foam panels, and soundproof insulation. The tools required for this project include a circular saw, a jigsaw, a drill, a measuring tape, and a hammer.

It is important to note that the thickness of the plywood sheets and the quality of the acoustic foam panels and soundproof insulation will greatly affect the effectiveness of the soundproofing. Thicker plywood and higher quality materials will provide better soundproofing results. Additionally, it is recommended to wear protective gear such as safety glasses and earplugs while using power tools for this project.

Choosing the Right Location for Your DIY Generator Box

Selecting the right location for your DIY generator box is crucial in ensuring optimal performance. The location should be far from any living areas and should have adequate ventilation to prevent the buildup of harmful gases. Ensure that the location you choose is flat and solid enough to support your generator box.

Another important factor to consider when choosing the location for your DIY generator box is the proximity to your fuel source. It is recommended to place the generator box close to the fuel source to minimize the length of the fuel line and reduce the risk of leaks. Additionally, make sure that the location is easily accessible for refueling and maintenance purposes.

Measuring and Cutting the Plywood Sheets for Your Soundproof Generator Box

The first step in building a soundproof generator box is measuring and cutting the plywood sheets. You will need to measure and cut the plywood sheets to fit the dimensions of your generator. Make sure you leave enough space around the generator to allow for ventilation, clearance, and maintenance.

Once you have measured and marked the plywood sheets, use a circular saw or jigsaw to cut them to size. Make sure to wear protective gear, such as safety glasses and gloves, while cutting the plywood sheets.

After cutting the plywood sheets, sand the edges to remove any roughness or splinters. This will ensure a smooth and even surface for assembling the soundproof generator box.

Assembling the Frame of Your DIY Generator Box

Once you have measured and cut the plywood sheets, you should proceed to assemble the frame of your generator box. You will need to use the screws to join the pieces of the plywood sheets together. Be sure to follow the design plan to avoid making mistakes and ensure that the generator box is stable.

It is important to note that the type and size of screws you use will depend on the thickness of the plywood sheets you are using. If the screws are too short, they may not hold the plywood together securely, while screws that are too long may split the wood. Additionally, you may want to consider using wood glue in addition to screws for added stability. Apply the glue to the joints before screwing the pieces together, and clamp them in place until the glue dries.

Adding Soundproof Insulation to Your Generator Box

Soundproof insulation helps to control and reduce the transmission of noise levels within the generator box. You can use acoustic floor mats or mineral wool to achieve optimal sound attenuation. Cut out pieces of insulation and place them between the plywood sheets before fastening them together with screws.

It is important to note that the thickness and density of the insulation material will affect the level of sound reduction. Thicker and denser materials will provide better soundproofing, but may also add more weight to the generator box. Consider the size and weight of your generator before selecting the insulation material.

In addition to soundproofing, insulation can also help regulate the temperature inside the generator box. This is especially important in colder climates where the generator may struggle to start in low temperatures. Insulation can help keep the generator warm and prevent fuel from freezing, ensuring that it starts up smoothly when needed.

Creating Ventilation Holes for the Exhaust and Cooling System

Generator boxes should have adequate ventilation to dissipate heat and exhaust fumes. Create ventilation holes to allow the exhaust and cooling system to function correctly. Ensure that the ventilation holes are not too large as this could affect the sound-dampening ability of the generator box.

It is important to consider the placement of the ventilation holes when creating them. The holes should be placed in a way that allows for proper air flow and prevents any debris or water from entering the generator box. Additionally, it is recommended to install a protective mesh over the ventilation holes to prevent any animals or insects from entering the box and causing damage to the generator or its components.

Installing Acoustic Foam Panels to Reduce Noise Levels Further

Acoustic foam panels are installed on the inner surfaces of the generator box to reduce noise levels. The panels absorb and dissipate sound waves, reducing the amount of noise transmitted from the generator. Cut out the foam panels to the size of the plywood sheets and adhere them using glue or double-sided tape.

It is important to note that the thickness and density of the acoustic foam panels will affect their effectiveness in reducing noise levels. Thicker and denser foam panels will provide better sound absorption than thinner and less dense ones. Therefore, it is recommended to choose foam panels with a thickness of at least 2 inches and a density of 1.5 pounds per cubic foot.

In addition to reducing noise levels, acoustic foam panels can also improve the overall sound quality of the generator. By absorbing unwanted echoes and reverberations, the panels can create a more pleasant and consistent sound. This can be particularly beneficial in environments where the generator is used for music or video production.

Securing the Box with Hinges and Latches for Easy Access and Maintenance

Securing the generator box with hinges and latches makes it easy to access and maintain the generator. Use suitable hinges and latches that can withstand the weight of the generator and allow for easy opening and closing of the generator box.

It is important to regularly check the hinges and latches to ensure they are in good condition and functioning properly. Loose or damaged hinges and latches can compromise the security of the generator box and make it difficult to access and maintain the generator. Lubricate the hinges and latches as needed to prevent rust and ensure smooth operation.

Painting or Staining Your Soundproof Generator Box to Match Its Surroundings

You may choose to paint or stain your soundproof generator box to match the surrounding environment. Use an outdoor paint or stain to make the generator box more aesthetically pleasing while protecting it from weather elements.

When selecting a paint or stain, consider the color and texture of the surrounding environment. If your generator box is located in a wooded area, you may want to choose a stain that matches the natural wood tones of the trees. Alternatively, if your generator box is located in a more urban environment, you may want to choose a paint color that matches the color of nearby buildings or structures.

It is important to properly prepare the surface of the generator box before applying any paint or stain. Clean the surface thoroughly and allow it to dry completely before applying any product. You may also need to sand the surface to ensure that the paint or stain adheres properly.

Testing Your DIY Soundproof Generator Box to Ensure Optimal Performance

Test your DIY soundproof generator box to ensure that it is functioning correctly. Carry out a sound level test to determine the amount of noise the generator produces while inside the generator box. Adjust the insulation, ventilation, or foam panels to achieve optimal results.

Tips for Maintaining and Cleaning Your Soundproof Generator Box Over Time

Maintaining and cleaning your generator box is crucial in ensuring the longevity and optimal performance of your generator. Avoid exposing the generator box to weather elements such as rain, snow, or extreme sunlight. Regularly check the insulation, ventilation, and foam panels to ensure that they are functioning correctly. Clean the surface of the generator box regularly to remove any dirt or debris that may affect its performance.

Benefits of Building Your Own Soundproof Generator Box vs Buying One Pre-Made

Building your own soundproof generator box offers more flexibility and control over the design and performance of the generator box. You can adjust the sound insulation and ventilation features to suit your needs, resulting in a generator that produces less noise than commercially available soundproof generator boxes. Building your soundproof generator box is also more cost-effective in the long term as compared to buying one pre-made.

Building a soundproof generator box is an excellent way to reduce the noise levels produced by your generator while also protecting it from outdoor elements. With the right tools and materials, anyone can build their DIY soundproof generator box and enjoy uninterrupted power supply without disrupting their peace and quiet.