Metal roofs are widely used in both residential and commercial buildings, providing a durable and long-lasting solution for roofing needs. However, one of the downsides of metal roofs is that they can be quite noisy, especially during heavy rain or hailstorms. This can be a major issue for homeowners or business owners who want to reduce the noise levels in their buildings. One of the best solutions for this is to use sound deadening paint. In this guide, we will take a closer look at sound deadening paint for metal roofs, its benefits, types, factors to consider before choosing, application tips, and more.

Why Metal Roofs Can Be Noisy

Metal roofs can be noisy because they are made of thin sheets of metal, which are prone to vibration when exposed to external forces such as rain, wind, or hail. The noise created by metal roofs can vary depending on several factors, including the type of metal used, the thickness of the metal sheets, and the design of the roof. For example, corrugated metal roofs can be more prone to noise than standing seam metal roofs, as the former have larger exposed areas that can vibrate.

However, it is important to note that not all metal roofs are noisy. Proper installation and insulation can significantly reduce the amount of noise produced by a metal roof. Additionally, some homeowners actually prefer the sound of rain on a metal roof, finding it soothing and relaxing. Ultimately, the decision to install a metal roof should be based on a variety of factors, including durability, energy efficiency, and aesthetic appeal, rather than just the potential for noise.

Introduction to Sound Deadening Paint

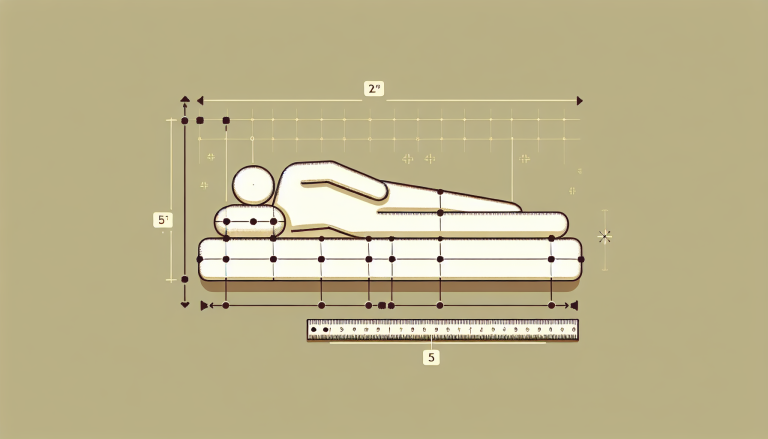

Sound deadening paint is a type of paint that is specially designed to absorb or dampen sound waves. It is typically made of a mixture of sound-absorbing materials and resins that provide a thick and durable finish. When applied to metal roofs, sound deadening paint helps to reduce the noise level by preventing the metal sheets from vibrating. This results in a quieter and more comfortable indoor environment.

Sound deadening paint can also be used in other applications, such as on walls, ceilings, and floors. It is particularly useful in buildings located near busy roads, airports, or train tracks, where noise pollution can be a major issue. In addition to reducing noise levels, sound deadening paint can also improve the overall acoustics of a room, making it easier to hear and understand speech and music. It is a cost-effective and easy-to-install solution for anyone looking to improve the sound quality of their living or working space.

Benefits of Using Sound Deadening Paint on Metal Roofs

There are several benefits of using sound deadening paint on metal roofs. Firstly, it helps to reduce the noise level inside the building, making it more comfortable and quieter for the occupants. Secondly, it can improve the thermal performance of the roof by reducing heat transfer through the metal sheets. This can help to lower energy bills and improve indoor comfort. Thirdly, sound deadening paint can extend the lifespan of the metal roof by providing a protective coating that prevents rust and corrosion.

Another benefit of using sound deadening paint on metal roofs is that it can improve the overall aesthetic of the building. The paint can be customized to match the color of the roof or the building, creating a more cohesive and visually appealing look. Additionally, sound deadening paint can also help to reduce the amount of maintenance required for the roof, as it can protect against damage from weather and other environmental factors.

It is important to note that the application of sound deadening paint on metal roofs should be done by a professional, as it requires specialized equipment and knowledge. However, the investment in sound deadening paint can provide long-term benefits for the building and its occupants, making it a worthwhile consideration for those looking to improve the performance and appearance of their metal roof.

Different Types of Sound Deadening Paint for Metal Roofs

There are several types of sound deadening paint available in the market. These include water-based, oil-based, and epoxy-based paints. Water-based sound deadening paints are the most eco-friendly and easy to apply, but they may not be as durable as oil-based or epoxy-based paints. Oil-based paints are more durable and resistant to weathering, but they can be more difficult to clean up and may emit volatile organic compounds (VOCs). Epoxy-based paints are the most durable and long-lasting, but they require extensive surface preparation and can be quite expensive.

It is important to consider the specific needs of your metal roof when choosing a sound deadening paint. For example, if your roof is located in an area with high humidity or frequent rainfall, you may want to opt for a paint that is specifically designed to resist moisture. Additionally, if your roof is exposed to extreme temperatures or harsh weather conditions, you may want to choose a paint that offers additional protection against UV rays and other environmental factors. Consulting with a professional or doing thorough research can help you make an informed decision about which type of sound deadening paint is best for your metal roof.

Factors to Consider Before Choosing Sound Deadening Paint for Your Metal Roof

Before choosing sound deadening paint for your metal roof, there are several factors that you should consider. These include the type of metal used in the roof, the design of the roof, the climate in your area, and your budget. For example, if your metal roof is prone to rust or corrosion, you may want to choose an epoxy-based paint that provides better protection than water-based or oil-based paints. Likewise, if you live in an area with harsh weather conditions, you may want to choose a paint that is more durable and weather-resistant.

Another important factor to consider is the color of the paint. Darker colors tend to absorb more heat, which can cause your metal roof to expand and contract, leading to potential damage over time. Lighter colors, on the other hand, reflect more heat and can help to keep your roof cooler. Additionally, you may want to consider the environmental impact of the paint you choose. Look for paints that are low in volatile organic compounds (VOCs) and are environmentally friendly.

How to Prepare Your Metal Roof for Sound Deadening Paint Application

The success of sound deadening paint application on metal roofs largely depends on proper surface preparation. Firstly, you need to clean the roof surface thoroughly to remove any dirt, debris, or rust. This can be done using a pressure washer or a scrub brush and a mild detergent. Secondly, you need to repair any dents, cracks, or holes in the metal sheets using a metal patch or filler. Thirdly, you need to prime the surface using a metal primer that is compatible with the sound deadening paint you will be using. This will help to improve adhesion and ensure a long-lasting finish.

Once the surface has been properly prepared, you can begin applying the sound deadening paint. It is important to follow the manufacturer’s instructions carefully, as the application process may vary depending on the type of paint you are using. Generally, you will need to apply the paint in thin, even coats, allowing each coat to dry completely before applying the next. It is also important to wear protective gear, such as gloves and a respirator, to avoid inhaling any fumes or getting the paint on your skin.

After the paint has been applied, it is important to allow it to dry completely before exposing it to any moisture or weather conditions. This can take anywhere from a few hours to a few days, depending on the type of paint and the weather conditions in your area. Once the paint is dry, you can enjoy the benefits of a quieter, more comfortable home or workspace, with reduced noise levels and improved insulation.

Step-by-Step Guide to Applying Sound Deadening Paint on Your Metal Roof

Once your metal roof is prepared, you can proceed to apply the sound deadening paint. Here are the steps:

- Stir the sound deadening paint thoroughly to ensure an even consistency.

- Apply the paint using a roller or a sprayer, starting from the top of the roof and working your way down.

- Apply the paint in thin, even coats, allowing each coat to dry completely before applying the next one.

- Apply at least two coats of paint, or as recommended by the manufacturer, to achieve optimal sound deadening performance.

- Clean up any spills or drips immediately using a damp cloth or a solvent recommended by the manufacturer.

It is important to note that sound deadening paint should only be applied to a clean and dry surface. Any dirt, debris, or moisture on the metal roof can affect the adhesion and performance of the paint. Therefore, it is recommended to thoroughly clean and dry the roof before applying the sound deadening paint.

Tips for Achieving Optimal Results with Sound Deadening Paint

Here are some tips to help you achieve optimal results when using sound deadening paint on your metal roof:

- Choose the right type of sound deadening paint for your roof based on your specific needs and budget.

- Ensure proper surface preparation before applying the paint, including cleaning, repairing, and priming.

- Apply the paint in thin, even coats, using a roller or a sprayer.

- Allow each coat to dry completely before applying the next one.

- Apply at least two coats of paint, or as recommended by the manufacturer, for optimal sound deadening performance.

- Protect yourself from paint fumes by wearing a respirator and working in a well-ventilated area.

By following these tips, you can ensure a successful sound deadening paint application on your metal roof, resulting in a quieter and more comfortable indoor environment.

It is important to note that sound deadening paint may not completely eliminate all noise from your metal roof. While it can significantly reduce noise levels, other factors such as the type of metal, the thickness of the roof, and the surrounding environment can also affect noise levels. Therefore, it is recommended to use sound deadening paint in combination with other noise reduction methods, such as insulation or acoustic panels, for optimal results.