Acoustic foam plays a vital role in soundproofing for recording studios, home theaters, and other spaces where sound quality matters. If you’re looking for a temporary solution for soundproofing your space, mounting acoustic foam panels could be the answer. Here’s a step-by-step guide on how to mount acoustic foam temporarily:

Understanding the Importance of Acoustic Foam in Soundproofing

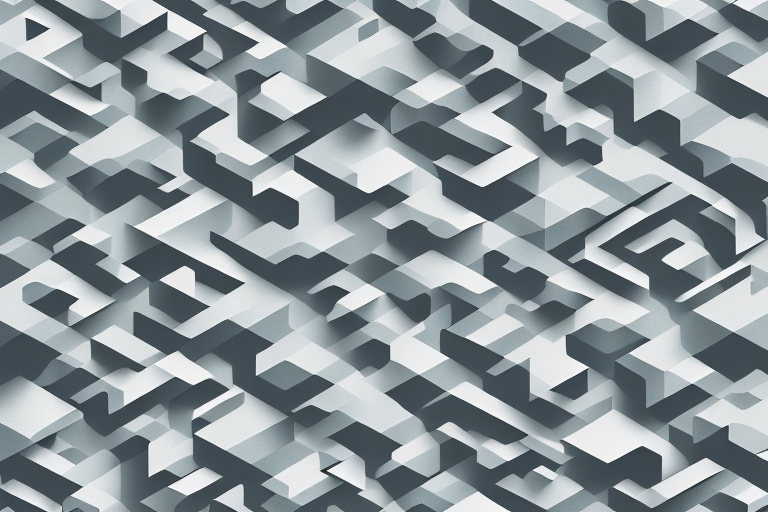

Before we dive into the specifics of mounting acoustic foam, it’s important to understand its role in soundproofing. Acoustic foam is designed to absorb echoes, reverberation, and unwanted noise in a space. By doing so, it can prevent sound from escaping or entering the room. The foam is made of open-celled polyurethane or polyester, which provides excellent sound absorption properties.

It’s worth noting that acoustic foam is not the same as soundproofing foam. While acoustic foam is designed to absorb sound waves within a room, soundproofing foam is meant to block sound from entering or leaving a space. Soundproofing foam is typically denser and thicker than acoustic foam, and is often used in conjunction with acoustic foam for maximum soundproofing effectiveness.

Choosing the Right Type of Acoustic Foam for Your Space

There are several types of acoustic foam available, each with its own unique properties. Depending on your specific soundproofing needs, you may need to consider foam thickness, density, and shape. Consider the size of your room and the areas where noise may be escaping or entering. High-density foam is best for preventing low-frequency sounds from escaping or entering the room, while thicker foam can help to combat higher frequency sounds.

Another important factor to consider when choosing acoustic foam is the shape of the foam. Pyramid-shaped foam is often used for sound absorption, as it helps to break up sound waves and prevent echoes. Wedge-shaped foam is also effective for sound absorption, but it is better suited for smaller spaces. If you have a larger room, you may want to consider using bass traps, which are designed to absorb low-frequency sounds.

It is also important to note that acoustic foam is not the only solution for soundproofing a room. Other options include soundproof curtains, double-paned windows, and even adding mass to walls and ceilings. When choosing the right type of acoustic foam for your space, it is important to consider all of your options and determine the best solution for your specific needs.

Necessary Tools and Materials for Mounting Acoustic Foam Temporarily

Before you start, you will need to gather the necessary tools and materials. These include:

- Acoustic foam panels

- Double-sided adhesive tape

- Measuring tape

- Marker

- Box cutter or scissors

- Clean cloth or sponge

It is important to note that the surface where you will be mounting the acoustic foam should be clean and dry. If the surface is dirty or has any residue, the adhesive tape may not stick properly. Additionally, it is recommended to let the adhesive tape sit on the surface for a few minutes before attaching the acoustic foam panels to ensure a stronger hold.

Preparing the Surface: Cleaning and Measuring

To ensure proper adhesion of the acoustic foam panels, you’ll need to clean the surface where they will be mounted. Use a clean cloth or sponge to wipe down the surface, removing any dirt or debris. Next, measure the area where you plan to install the foam panels. Use a marker to mark the location of each panel.

It’s important to note that the surface should also be completely dry before mounting the foam panels. Any moisture or dampness can affect the adhesive and cause the panels to fall off over time. If necessary, use a dry cloth or fan to ensure the surface is completely dry before proceeding.

Additionally, consider the placement of any furniture or equipment in the room. If there are large objects that may obstruct the sound waves, it may be necessary to adjust the placement of the foam panels to ensure maximum effectiveness. Take some time to plan out the placement of the panels before mounting them to the surface.

Creating a Layout Plan for the Acoustic Foam Panels

Before you start mounting the foam panels, it’s a good idea to create a layout plan. This will help you to determine the best placement for each panel and ensure that you have enough foam to cover the necessary area. Use your measurements to determine the number of panels you’ll need, and then lay them out on the floor in the desired pattern.

When creating your layout plan, consider the shape and size of the room, as well as any furniture or fixtures that may affect the acoustics. For example, if you have a large bookshelf or a piano in the room, you may need to adjust the placement of the foam panels to ensure that they are effectively absorbing sound waves.

It’s also important to consider the thickness and density of the foam panels. Thicker panels will absorb more sound, but may not be necessary for smaller rooms or spaces with low levels of ambient noise. Additionally, denser foam panels may be more effective at absorbing high-frequency sounds, while less dense panels may be better suited for low-frequency sounds.

Applying Double-Sided Adhesive Tape to the Back of Panels

One of the easiest ways to mount acoustic foam temporarily is to use double-sided adhesive tape. Cut the tape to the same size as the foam panel, and then apply it to the back of the panel. Be sure to apply enough tape to hold the panel securely in place.

It is important to note that double-sided adhesive tape may not be the best option for long-term mounting of acoustic foam. Over time, the adhesive may weaken and the foam panel may fall off. For a more permanent solution, consider using mounting brackets or screws to secure the panels to the wall.

How to Cut and Shape Acoustic Foam Panels for a Perfect Fit

If you need to customize the shape of your foam panels to fit in a specific area, you can use a box cutter or scissors. Carefully mark the area to be cut, and then use the blade to make a clean cut. Be sure to use caution when working with sharp objects.

It’s important to note that when cutting acoustic foam panels, you should avoid using a serrated blade as it can cause the foam to tear and create uneven edges. Instead, opt for a sharp, straight blade for a cleaner cut.

Once you have cut the foam panel to the desired shape, you can use sandpaper to smooth out any rough edges. This will not only improve the appearance of the panel but also ensure that it fits snugly against the wall or ceiling, providing maximum sound absorption.

Placing and Aligning Acoustic Foam Panels on Walls and Ceilings

Once you have prepared your foam panels and adhesive tape, it’s time to start mounting them. Begin with the first panel and carefully place it in the desired location. Be sure to align it according to your layout plan. Repeat this process for each panel, using your measuring tape to ensure that each panel is spaced evenly.

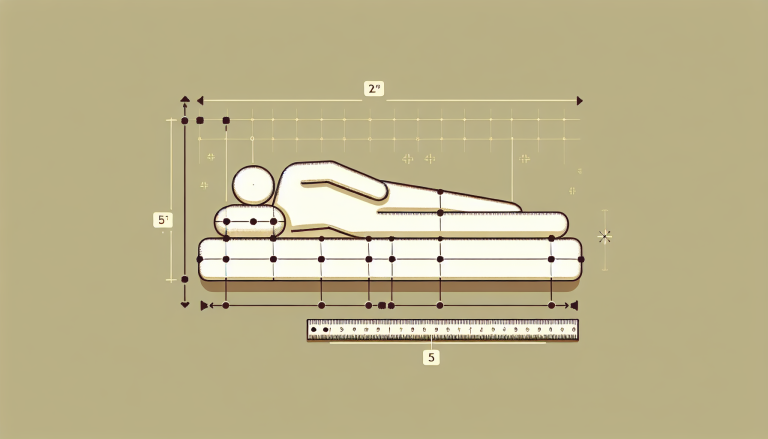

It’s important to note that the placement of your acoustic foam panels can greatly affect their effectiveness. For example, if you’re trying to reduce echo in a room, it’s best to place the panels on the walls opposite to each other. If you’re trying to reduce noise transmission between rooms, it’s best to place the panels on the shared wall. Additionally, it’s recommended to leave a small gap between the panel and the wall to allow for air circulation, which can improve the panel’s performance.

Tips for Achieving Maximum Soundproofing with Acoustic Foam

For maximum soundproofing benefits, it’s important to install your foam panels correctly. Be sure to cover as much surface area as possible, and focus on areas where sound may easily escape or enter your space. Additionally, you can consider adding bass traps to corners or other areas with high pressure sound waves.

Another important factor to consider when using acoustic foam for soundproofing is the thickness of the foam. Thicker foam panels are more effective at absorbing sound waves than thinner ones. Therefore, it’s recommended to use foam panels that are at least 2 inches thick for optimal soundproofing results.

It’s also important to note that acoustic foam is not a complete solution for soundproofing. While it can significantly reduce noise levels, it may not completely eliminate all sound. To achieve maximum soundproofing, it’s recommended to use a combination of acoustic foam, sound barriers, and other soundproofing materials.

Removing Acoustic Foam Panels without Damaging Walls or Ceilings

If you need to remove your acoustic foam panels, it’s important to do so carefully. Use a hairdryer to warm up the adhesive tape, making it easier to remove. Slowly and gently peel the foam away from the wall or ceiling, taking care not to damage the surface.

It’s also important to note that the longer the foam panels have been on the wall or ceiling, the more difficult they may be to remove. In some cases, the adhesive tape may leave behind residue or even damage the surface. To avoid this, consider using a specialized adhesive remover or contacting a professional to assist with the removal process.

Alternative Methods for Temporarily Mounting Acoustic Foam

If double-sided adhesive tape is not an option for you, there are other ways to mount acoustic foam temporarily. You can use poster strips or hook-and-loop fasteners, or even make your own mounting brackets using wire or thin metal rods.

By following these steps, you can create a temporary soundproofing solution that will help to improve the acoustics of your space. Whether you’re recording music, watching movies, or just need some peace and quiet, acoustic foam can make a big difference.

Another alternative method for temporarily mounting acoustic foam is using suction cups. Suction cups can be easily attached to the back of the foam and then pressed onto a smooth surface, such as a window or mirror. This method is particularly useful for those who want to remove the foam without leaving any residue or damage to the walls. However, it is important to note that suction cups may not work well on textured or uneven surfaces.