If you want to insulate your home more efficiently, one of the things you can do is fill your hollow core doors with foam. This can help reduce energy loss from your home, making it more comfortable and cost-effective. In this article, we’ll take you through the steps required to fill a hollow core door with foam insulation.

Why Fill a Hollow Core Door with Foam?

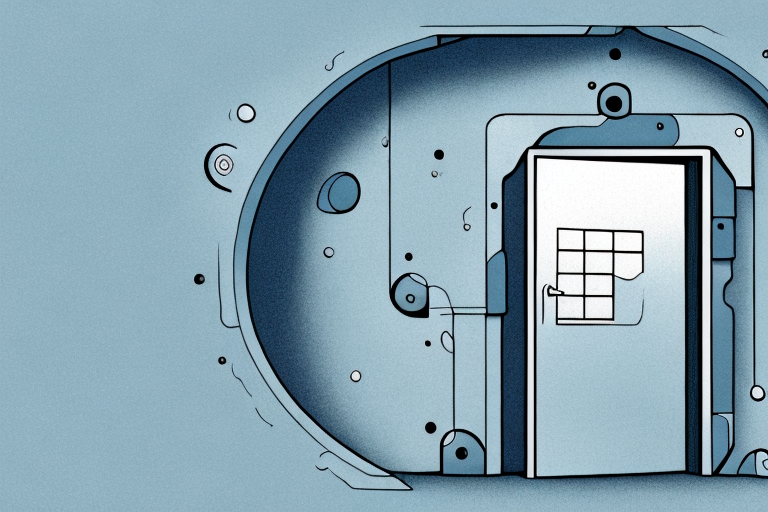

Hollow core doors are constructed with a honeycomb core, which can allow air to flow through and reduce the insulation effectiveness of the door. Filling the door with foam can help to block this airflow and increase insulation efficiency.

In addition to improving insulation efficiency, filling a hollow core door with foam can also help to reduce noise transmission. The foam acts as a sound barrier, absorbing and dampening sound waves that would otherwise pass through the door.

Another benefit of filling a hollow core door with foam is increased durability. The foam adds structural support to the door, making it less likely to warp or bend over time. This can extend the lifespan of the door and save money on replacement costs in the long run.

Understanding the Hollow Core Door Construction

Before you start the project, it’s important to understand how hollow core doors are constructed. The door consists of two flat panels, which are connected by an interior framework of wood strips. The space between these strips is typically filled with a honeycomb filling or cardboard, which can allow air to pass through.

One advantage of hollow core doors is that they are lightweight, making them easier to install and handle. They are also less expensive than solid wood doors, which can be a cost-effective option for those on a budget. However, because of their construction, they are not as durable or soundproof as solid wood doors.

It’s important to note that not all hollow core doors are created equal. Some may have a higher quality honeycomb filling or thicker wood strips in the interior framework, which can improve their durability and soundproofing capabilities. When selecting a hollow core door, it’s important to consider the intended use and location to ensure it will meet your needs.

Advantages of Filling a Hollow Core Door with Foam

Filling a hollow core door with foam can offer several advantages, including:

- Improved insulation efficiency, which can reduce heating and cooling costs.

- Better soundproofing, which can help reduce noise levels between rooms.

- Increased durability and stability, which can extend the lifespan of the door.

- Improved fire resistance, as foam can resist flames and smoke better than hollow core materials.

Another advantage of filling a hollow core door with foam is that it can help prevent the door from warping or bowing over time. This is because the foam provides additional support and stability to the door, which can help it maintain its shape and structure.

In addition, filling a hollow core door with foam can also improve the overall appearance of the door. This is because the foam can help fill in any gaps or imperfections in the door’s surface, creating a smoother and more uniform finish. This can be especially beneficial if you plan to paint or stain the door, as it can help ensure a more even and professional-looking result.

Materials and Tools Required for the Project

Before you begin the project, you’ll need to have the following materials and tools:

- Hollow core door

- Expanding foam insulation (such as Great Stuff)

- Drill

- Spade bit (1 1/2 inch)

- Wood filler or caulk

- Sander or sandpaper

- Paint or stain

It’s important to note that the type of expanding foam insulation you use can affect the outcome of the project. Some foams may expand too much and cause the door to warp or become misshapen. It’s recommended to use a foam specifically designed for door insulation, or to test a small area before applying it to the entire door.

Additionally, if you plan on painting or staining the door, it’s important to choose a product that is suitable for the type of wood the door is made of. Some woods may require a primer or special preparation before painting or staining, so be sure to research and follow the manufacturer’s instructions carefully.

Safety Precautions to Take Before Starting

Before you start the project, take the necessary safety precautions:

- Wear protective goggles and gloves to prevent foam from touching your skin or eyes.

- Work in a well-ventilated area to avoid inhaling fumes from the foam.

- Be careful when handling the door and the tools, to avoid injury or damage to the door and surroundings.

Additionally, it is important to have a first aid kit nearby in case of any accidents or injuries. Make sure you know how to use the tools properly and have a clear understanding of the project instructions before beginning.

Furthermore, if you are working with a partner, make sure to communicate effectively and establish a plan for handling any potential safety hazards. It is always better to be over-prepared when it comes to safety, so take the time to assess the risks and take the necessary precautions before starting the project.

Step 1: Removing the Door from Its Hinges

The first step to filling a hollow core door with foam is to remove it from its hinges. Place it on two sawhorses or a flat surface, with the interior facing up.

Before removing the door from its hinges, make sure to remove any hardware such as doorknobs, locks, and hinges. This will make the process easier and prevent any damage to the hardware.

It’s also important to wear protective gear such as gloves and safety glasses when working with foam. Foam can expand quickly and may cause skin irritation or eye damage if it comes into contact with your skin or eyes.

Step 2: Drilling Holes in the Door Surface

Next, use the drill and 1 1/2 inch spade bit to drill holes in the door surface. Space them out evenly, about 6 inches apart, and concentrate on the center of the door where the honeycomb or cardboard filling is located. Be careful not to drill all the way through, as this can damage the door or create visible holes on the other side.

After drilling the holes, use a vacuum cleaner to remove any debris or sawdust that may have accumulated on the door surface. This will ensure that the adhesive sticks properly to the door surface.

It is important to wear protective gear such as gloves and goggles while drilling holes in the door surface. This will protect you from any flying debris or accidental injuries that may occur during the process.

Step 3: Inserting the Foam Insulation into the Holes

Insert the foam insulation into the holes, starting from the bottom and working your way up. Use a steady, continuous motion to fill each hole, and avoid overfilling or underfilling any of them. It’s important to use expanding foam insulation, as it will fill the entire hollow space and create a solid barrier against airflow.

Once you have inserted the foam insulation into all the holes, allow it to dry completely before moving on to the next step. This usually takes around 24 hours, but can vary depending on the type of foam insulation you are using and the temperature and humidity of the environment.

After the foam insulation has dried, use a utility knife to trim any excess foam that may be protruding from the holes. This will ensure a clean and neat finish, and prevent any obstruction of the airflow. Once you have trimmed the excess foam, you can proceed with installing the final layer of drywall or plasterboard to complete the insulation process.

Step 4: Sealing the Holes with Wood Filler or Caulk

After the foam has dried completely (usually within a few hours), use wood filler or caulk to seal the holes. Apply enough to cover the surface of the door, and smooth out with a putty knife or your fingers. Wait for the filler to dry completely before sanding the surface.

It is important to choose the right type of wood filler or caulk for the job. For small holes, a water-based wood filler or acrylic caulk will work well. For larger holes, a two-part epoxy wood filler or silicone caulk may be necessary. Make sure to read the label and follow the manufacturer’s instructions for best results.

If you are painting the door, make sure to use a wood filler or caulk that is paintable. Some fillers and caulks may not adhere well to paint, causing the surface to crack or peel over time. Additionally, if you are staining the door, choose a filler or caulk that matches the color of the wood as closely as possible to ensure a seamless finish.

Step 5: Sanding and Painting the Door Surface

Sand the surface of the door lightly to remove any excess filler or rough spots. Then, paint or stain the door to your liking, and let it dry completely before reattaching it to the hinges.

Common Mistakes to Avoid When Filling a Hollow Core Door with Foam

Some common mistakes to avoid when filling a hollow core door with foam include:

- Drilling too deep or too many holes, which can weaken the door structure or create visible holes on the other side.

- Not using the right amount or type of foam, which can reduce insulation efficiency or cause the door to warp or bulge.

- Not sealing the holes properly, which can lead to air leaks or exposure to moisture.

Tips for Enhancing the Insulation Efficiency of Your Doors

In addition to filling your hollow core doors with foam, there are several other ways to enhance the insulation efficiency of your doors:

- Use weatherstripping around the door frame to prevent drafts and air leaks.

- Install a door sweep or threshold to block air from entering through the bottom of the door.

- Replace old or damaged doors with new, energy-efficient ones.

How to Determine If Your Door Needs Insulation

If you’re not sure whether your door needs insulation, you can perform a simple test:

- Hold a candle or a lighter near the edges of the door, and observe the flame. If it flickers or moves, there may be air leaks.

- Place your hand on the door surface, and feel for any cold spots. If you detect any, there may be insufficient insulation.

- Consider having a professional energy audit to identify areas of your home that need insulation or other energy-saving improvements.

Filling a hollow core door with foam can be a challenging but rewarding DIY project that can enhance the insulation efficiency, soundproofing, durability, and fire resistance of your home. By following the steps outlined in this article and taking the necessary safety precautions, you can achieve a successful result and enjoy the benefits of a better-insulated home.